It is important to keep the StabiFlow® and flow cells clean. This article explains maintenance suggestions to clean the assembly and identify its components.

How do I clean the Argon StabiFlow® and flow cells?

IMPORTANT: Take the Argon StabiFlow® off the wall to perform cleaning or when replacing parts.

Cleaning the StabiFlow® consists of two steps.

1. The inside membane that allows a fixed flow rate

2. The flow cell where the sensor is inserted

Cleaning the membrane

The membrane is located inside of the StabiFlow®.

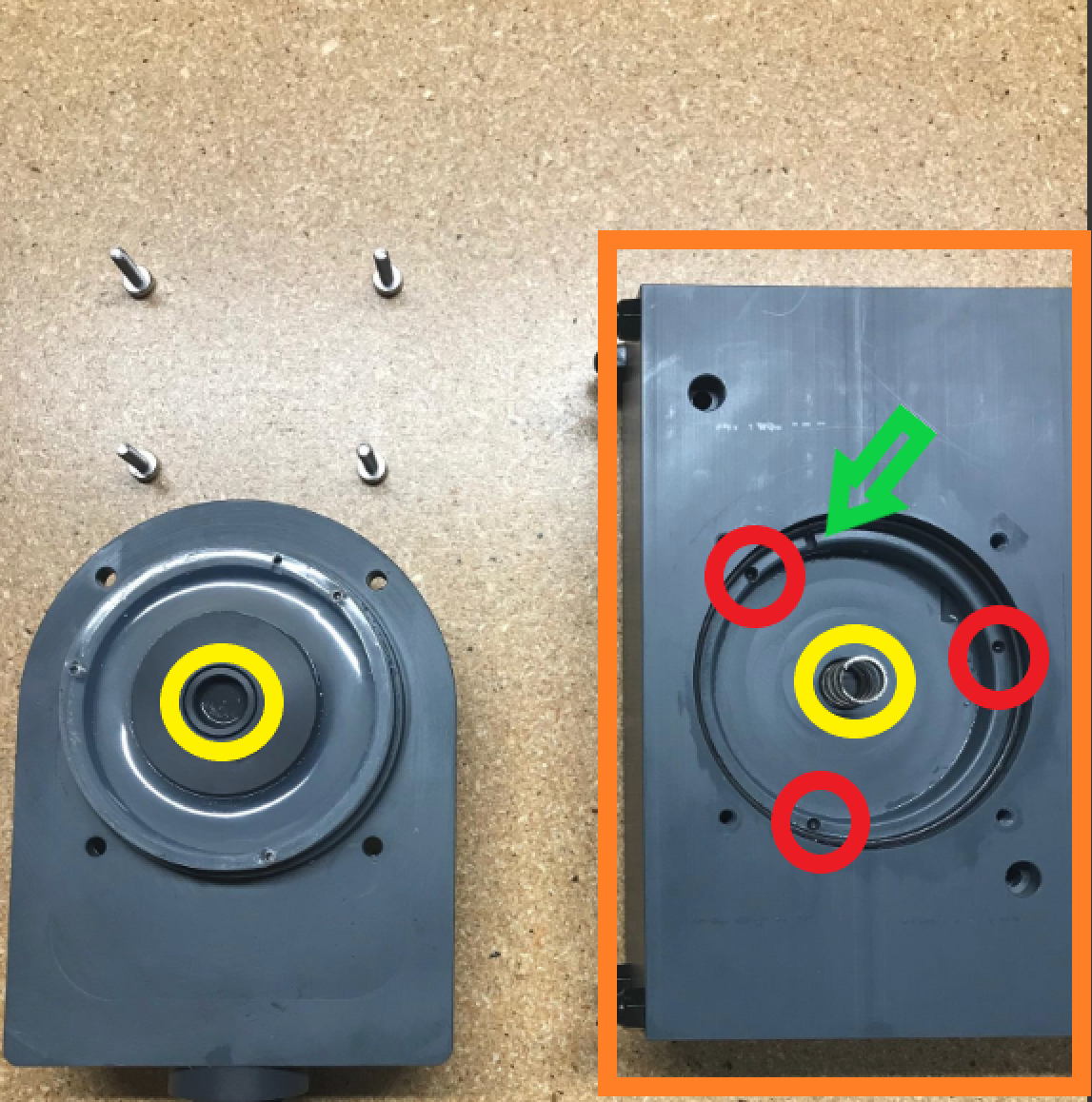

1. Access the membrane by removing the head screws

2. Open up the StabiFlow®. Wipe down the membrane, circled in red.

Note: The membrane is a thin plastic piece and can tear if not handled gently!

3. Once you wipe down the inside of the Stabiflow®, you can put it back together. The membrane is designed to only line up one way. There are 3 peg holes in the membrane and 1 hole for sample line flow. The flow hole has the green arrow and the peg holes are circled in red.

There is one large O-rings that keeps the membrane from leaking (shown by the blue arrow). Be sure that this O-ring and the plastic membrane are not compromised. The O-ring can become dry rotted over time and need replaced. In the case that it does become damaged, contact your Kuntze representative for the Argon Stabiflow® spare parts kit.

4. A spring puts pressure on the membrane and holds it in place when under pressure. Be sure that the spring lines up with the back of the membrane. Match the yellow circles, the 3 pegs (circled in red), and 1 flow hole (green arrow) with the holes of the main body (orange square).

Note: The PVC and surrounding parts were engineering with a thin tolerance. Take special attention that the PVC bodies, O-rings, and membrane are lined up properly before securing screws!

5. Reinstall the 4 head screws that you took out in Step 1.

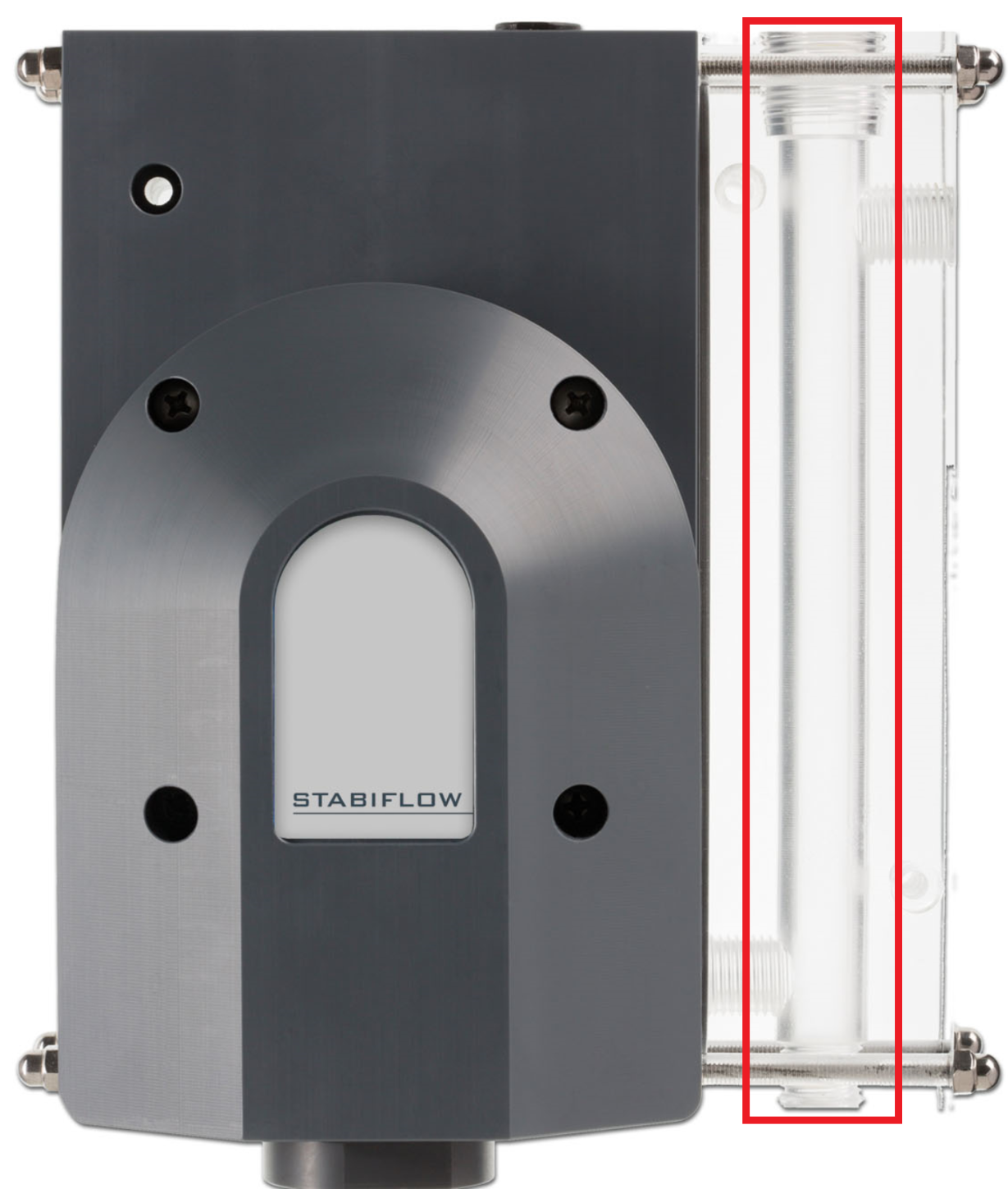

Cleaning the Flow cell

The Flow cell (squared in red) is an acrylic chamber that houses the sensors when in use. Its diameter is 15 mm or .59 inches. Use a nylon tube brush, slightly larger than 15 mm, to ensure the sides of the flow cell are cleaned.

Note: Too large of a diameter and different brush materials are more likely to cause damage to the acrylic chamber.

Comments

0 comments

Please sign in to leave a comment.